-

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

MOQ:

Default

MOQ:

Default

Port:

Hangzhou

Port:

Hangzhou

Packaging:

Customizable

Packaging:

Customizable

Lead Time:

Default

Lead Time:

Default

Size:

Default Size

Size:

Default Size

Color:

Default Color

Color:

Default Color

Colour : Black /white /red/yellow/orange/blue

HDPE Sheet Thickness: 2-200 mm, 0.2-3 mm

HDPE Sheet format: 1220 ×2440 mm, 1000×2000 mm

High-Density Polyethylene (HDPE) sheet is robust against impact and abrasion-resistant, exhibiting a low coefficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). The material's durability makes it a perfect match for various applications, including water tanks, chute linings, bottle/bottle cap production, and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

High-density Polyethylene, also known as HDPE, is made from a chain of ethylene molecules (the poly part of polyethylene) and is famous for its lightweight and high durability.

The preference for HDPE sheets is increasing significantly in the market today, as they can reduce the material used for producing and packaging products due to their strength and weight.

It is also available at Tap Plastics in sheet form with either a smooth or textured surface. The textured surface is also known as a cutting board. Both smooth and textured surfaces are FDA-approved for use in food contact applications.

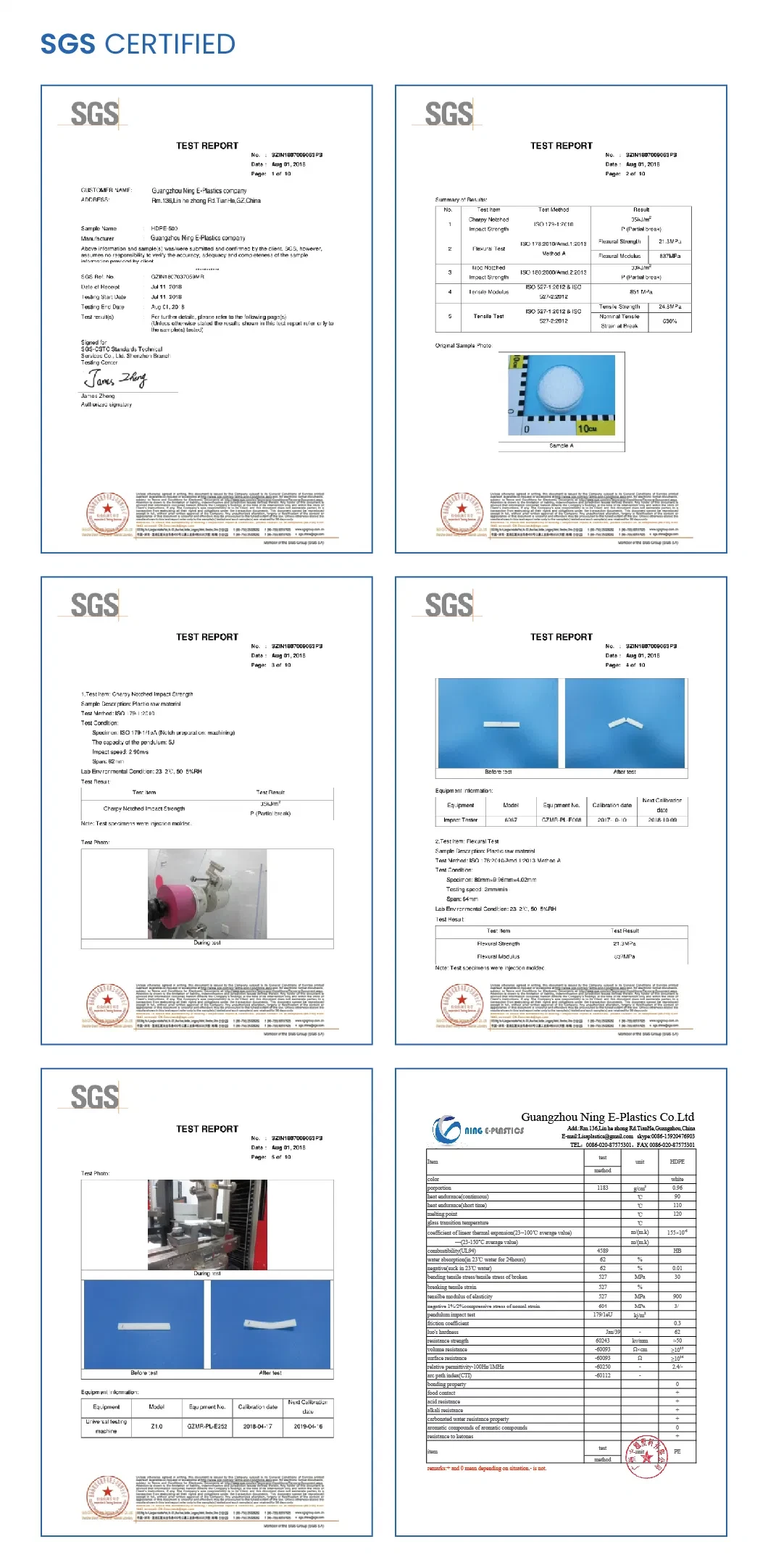

| Item | RESULT | UNIT | PARAMETER | NORM USED |

| Mechanical properties | ||||

| Modulus of elasticity | 1000 | MPa | In tension | DIN EN ISO 527-2 |

| Modulus of elasticity | 1000 - 1400 | MPa | In flexure | DIN EN ISO 527-2 |

| Tensile strength at yield | 25 | MPa | 50 mm/min | DIN EN ISO 527-2 |

| Impact strength (Charpy) | 140 | Kj/m 2 | Max. 7,5j | |

| Notched Impact stren. (Charpy) | No break | Kj/m 2 | Max. 7,5j | |

| Ball indentation hardness | 50 | MPa | ISO 2039-1 | |

| Creep rupture strength | 12,50 | MPa | After 1000 hours static load 1% elong. after 1000 hours Against steel p=0,05 N/mm 2 | |

| Time yield limit | 3 | MPa | ||

| Coefficient of friction | 0,29 | ------ | ||

| Thermal properties | ||||

| Glass transition temperature | -95 | °C | DIN 53765 | |

| Crystalline melting point | 130 | °C | DIN 53765 | |

| Service temperature | 90 | °C | Short term | |

| Service temperature | 80 | °C | Long term | |

| Thermal expansion | 13 - 15 | 10-5K-1 | DIN 53483 | |

| Specific heat | 1,70 - 2,00 | J/(g+K) | ISO 22007-4:2008 | |

| Thermal conductivity | 0,35 - 0,43 | W/(K+m) | ISO 22007-4:2008 | |

| Heat distorsion temperature | 42 - 49 | °C | Method A | R75 |

| Heat distorsion temperature | 70 - 85 | °C | Method B | R75 |