-

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Rm.136,Lin he Zhong Rd. TianHe, Guangzhou, China.

Colour : Black /white /red/yellow/orange/blue

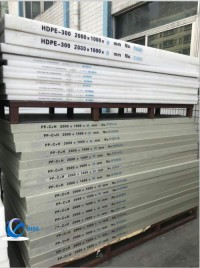

HDPE Sheet Thickness: 2-200 mm, 0.2-3 mm

HDPE Sheet Size: Length: 1220 mm, 1000×2000 mm

High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low coefficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). Its durability makes it a perfect match for various applications such as water tanks, chute linings, bottle/bottle cap production, and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

High-density Poly Ethylene, also known as HDPE, is made from a cord of ethylene molecules (the poly part of polyethylene). It is famous for its lightweight and high durability.

The preference for HDPE sheets is increasing by leaps and bounds in the market today, as it can cut down on the material used for producing and packaging products for their strength and weight.

It is also available at tap plastics in sheet form with either a smooth or textured surface. The textured surface is also called a cutting board. Both smooth and textured surfaces are FDA approved for food contact.

HDPE sheets are expanded into multiple types; each type has different applications and uses, such as;

HDPE sheet comes with a textured surface known as HDPE Matte sheet. This type of sheet is designed to produce items like cutting boards. HDPE Matte is acid resistant, reliable with FDA controls, and certified by the National Sanitation Foundation (NSF).

It is best for food preparation as it won’t make your knives dull and doesn’t harbor bacteria.

Smooth HDPE sheeting is ideal for those applications which need good abrasion resistance and low friction. It comprises multiple features which make it versatile for many applications. Tank linking is the best yet most common example of a smooth HDPE sheet application.

Smooth HDPE is effortlessly created and includes excellent compound protection elasticity, and is dampness and effect-safe.

This kind of HDPE plastic sheet features a more advanced performance than standard HDPE sheeting. The enhanced highlights of HDPE pipe grade make it the most well-known HDPE sheet for open-air applications.

| ITEM

|

TEST | UNIT | HDPE | |||

| METHOD | WHITE | |||||

| color | ||||||

| proportion | 1183 | g/cm3 | 0.96 | |||

| heat endurance(continuous) | ºC | 90 | ||||

| heat endurance(short time) | ºC | 110 | ||||

| melting point | ºC | 120 | ||||

| glass transition temperature | ºC | |||||

| coefficient of linear thermal expansion(23-100ºC average value) | m/(m.k) | 155×10-6 | ||||

| -(23-150°C average value) | m/(m.k) | |||||

| combustibility(UL94) | 4589 | HB | ||||

| water absorption(in 23ºC water for 24hours) | 62 | % | ||||

| negative(suck in 23ºC water) | 62 | % | 0.01 | |||

| bending tensile stress/tensile stress of broken | 527 | MPa | 30 | |||

| breaking tensile strain | 527 | % | ||||

| tensile modulus of elasticity | 527 | MPa | 900 | |||

| negative 1%/2%compressive stress of normal strain | 604 | MPa | 3/- | |||

| pendulum impact test | 179/1eU | kj/m2 | ||||

| friction coefficient | 0.3 | |||||

| luo’s hardness | Jan/39 | – | 62 | |||

| resistance strength | 60243 | kv/mm | >50 | |||

| volume resistance | -60093 | Ω×cm | ≥1015 | |||

| surface resistance | -60093 | Ω | ≥1016 | |||

| relative permittivity-100Hz/1MHz | -60250 | – | 2.4/- | |||

| arc path index(CTI) | -60112 | – | ||||

| bonding property | 0 | |||||

| food contact | + | |||||

| acid resistance | + | |||||

| alkali resistance | + | |||||

| carbonated water resistance property | + | |||||

| aromatic compounds of aromatic compounds | 0 | |||||

| resistance to ketones | + | |||||

| item | test | unit | PE | |||

| method |

Remarks:+ and 0 mean depending on the situation.- is not.